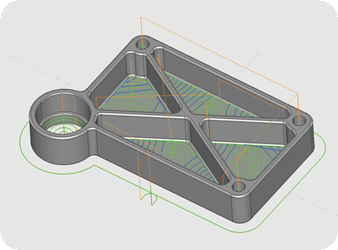

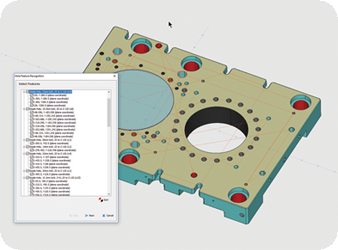

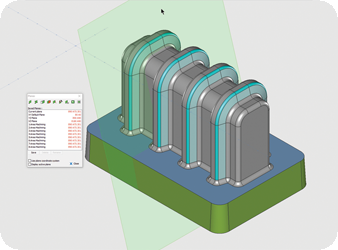

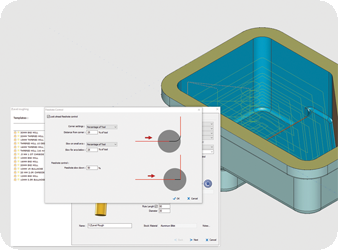

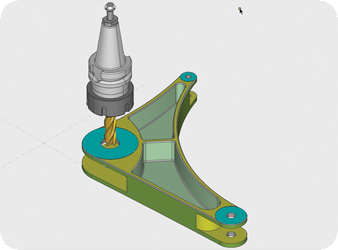

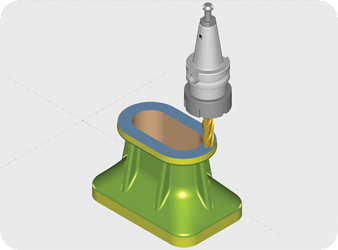

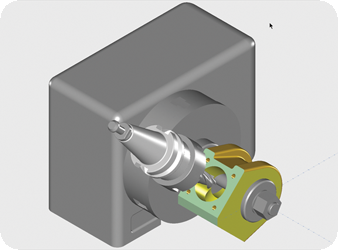

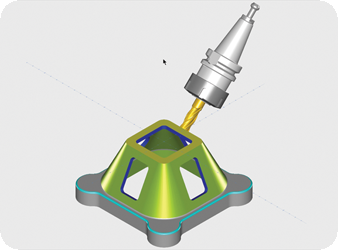

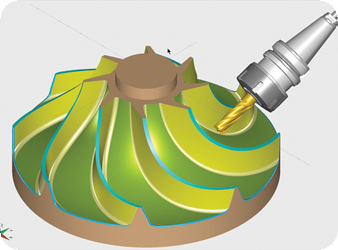

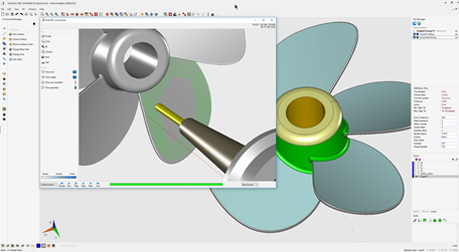

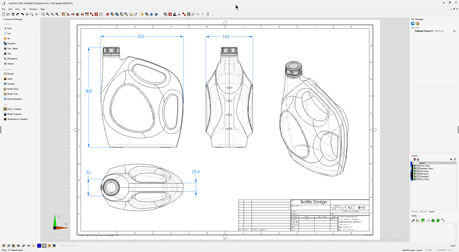

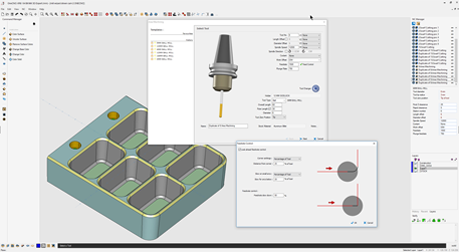

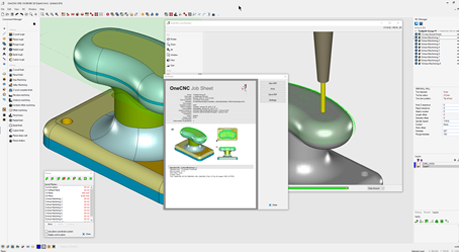

OneCNC Mill offers a complete range of solutions to produce parts from 2D/3D to multi-axis. Your customer base may include automotive, aerospace and medical or consumer products, OneCNC Mill includes functionality to suit all of these applications.

OneCNC Mill toolpaths include OneCNC’s Active Cut technology to provide efficient methods of creating parts. OneCNC Mill is a fully integrated CAD CAM, it’s fast, easy, and productive without the need of other software.