Marvo Technologies B.V. is a specialised metal-turning company in the city of Tilburg, in the Netherlands. Typical batch quantities can extend to 10,000 to 15,000 or more workpieces from a range on materials from aluminium to hardened steel.

On completion of an investigation of many CAD-CAM systems in 2008, Marvo ordered the highest level OneCNC Lathe system, CYB and implemented it in January 2009. A wide range of machine configurations made the choice of a CAD-CAM system a little difficult. With OneCNC Marvo are now making reliably, efficient programs for all their machines, and new orders have been undertaken which would have been previously impossible to produce.

‘We looked at other systems, some costing 2-3 times the cost of OneCNC, but in the important aspects of how we work, they did not offer more than OneCNC …..and quite often very much less. OneCNC is working above our expectations, we are very pleased.’

Seen in this video is the Gildemeister 42T Linear running a test part in aluminium.

Marvo Technologies B.V.

Minosstraat 10

5048 CK Tilburg

Netherlands

Phone: +31 13 5729610

Fax +31 13 5729620

Link to Marvo website: http://www.marvo.nl

Inspiration + OneCNC + CNC = T - Rod

The company Technop GmbH, since 1994 on the market based in Plankstadt , Baden-Württemberg, has been one of the first customers for OneCNC Germany. The owner Martin Preuss started in 2001 with multiple versions from OneCNC and continually updated his software. Because of that Technop GmbH is able to use all their machinery efficient and fully utilized.

In 2004 Martin Preuss got together with Luigi Colani, a Star designer, at his exhibition hall in Karlsruhe. After some discussions about a new car the product range of Martin Preuss was unexpectedly larger.

Technop GmbH built the prototype of the sensational vehicle, a Street-Ray. They used OneCNC for the whole construction of the 2D and 3D parts, which were compiled as NC code and transmitted into the CNC lathe and milling machines for production directly used.

This inspired Martin Preuss for his own further development, a T-Rod. He used OneCNC to create and construct again and all the parts are perfectly built using the CNC programs. Here are some impressions of this impressive vehicle:

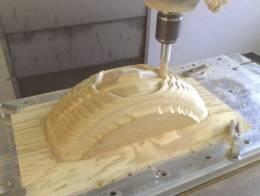

Here we see one of the many parts for the shell being CNC machined:

Here we see the part after completion of machining and finishing:

Here we see a CNC lathe part being machined:

Here we see the details of the front wheel assembly:

Here is another view of the T-Rod:

For further information please visit the web sites or contact Martin Preuss.

Contact:

Technop GmbH, Gewerbering 24, D-68723 Plankstadt,

Fon: +49 6202 13524

Fax: +49 6202 13513

Homepage: www.technop.de or http://www.t-rod.com/

Tokyo Polytechnic University, "Intelligent Robot Laboratory" in collaboration with the private sector is conducting teaching research in a unique and extensive experience with research and development.

OneCNC Japan had previously supplied OneCNCXR3 and a visit was made to see how the software was involved in the production of parts in the laboratory. We spoke with Mr. Ikeda Ph.D, Research Associate and Mr. Yamaguchi who is in a masters course and discussed the work that was being performed by the laboratory using OneCNC.

Mr. Ikeda explained the main purpose of the introduction of OneCNC and CNC machining was "cost savings" which was necessary for the budget of the laboratory.

The laboratory also required shorter lead times in processing of the required parts.

We were surprised to find OneCNC so competitively priced for such a good product that included 3 dimensional simulation that we required.

We purchased OneCNC and found we could use it immediately after installation without any formal training. The OneCNC operation was easy to grasp and a very good user interface helped us to use it.

Mr. Yamaguchi explained that machining gear cases for example the tool paths has very smooth movements and short processing times.

Until the final shape is machined the HSM tool paths has such good constant load control that there are no part failures during the machining even on thin walled parts leaving the parts all left intact and accurate.

Mr. Ikeda said we first purchased OneCNCXR3 Mill Express and recognized it's value and soon decided to upgrade to OneCNCXR3 Mill Expert in one month.

Here are some covers for the submarine project the laboratory is building.

As a result of the introduction of OneCNC and NC machining it should pay for itself within a year and in this time provide many advantages for the future creating more efficient parts.

OneCNC and NC machining provides an important part of our research and development process which requires a lot of trial and error and extensive re-manufacture of items in the design process.

Dr. Ikeda (left) Mr. Yamaguchi, in masters course (right)

Profile:

Tokyo Polytechnic University "Intelligent Robot Lab".

1583 Iiyama Atsugi, Kanagawa Prefecture.

Research:

Robot leg formula (2 dimensional plane)

Robot leg formula (3 dimensional space)

Floating posture of robot control

Mobile underwater (submarine) control

Two robot dinosaur

URL: http://www.runbot.jp