OneCNCXR6 is Released

OneCNC is proud to announce OneCNCXR6 is officially released as a new upgrade of the software simultaneously released in all versions.OneCNC advises that all new full systems purchased since 1st March 2014 are eligible for a free upgrade to OneCNCXR6 same version purchased od OneCNCXR5.

Overview of OneCNCXR6

There are many exclusive new features in OneCNCXR6 including 2D and 3D total collision checking for tooling and machined parts in the milling versions. OneCNCXR6 continues the tradition of having a free maintenance plan for the life of the software until the next version is released ensuring that the software is kept up-to-date with free downloads and support from the update server during this time. OneCNCXR6 is the most technologically advanced release developed in the 30 plus of years OneCNC development.

OneCNCXR6 is about improving the technology of the overall systems. This major undertaking provides a complete 64 Bit application release version still supports a 32 Bit application by automatic install.

OneCNCXR6 utilizes the latest Windows 8 technologies including native 64-bit support resulting in superior performance, especially when working on large or complex designs. OneCNC understands that many users in manufacturing still use earlier Windows XP versions and still supports these users with an automated installation for 32 Bit versions.

OneCNCXR6 is designed to take advantage of the latest multi-core systems. Multi-core depending on the operating system support can dramatically increase speed generation of some complex tool paths and is beneficial not only when generating multiple operations or performing simulation tasks, but also when generating a single tool paths.

All of this happens from an automated installation that checks the operating system being used and installs the most advanced version to suit the Windows version of the user’s operating system on the PC.

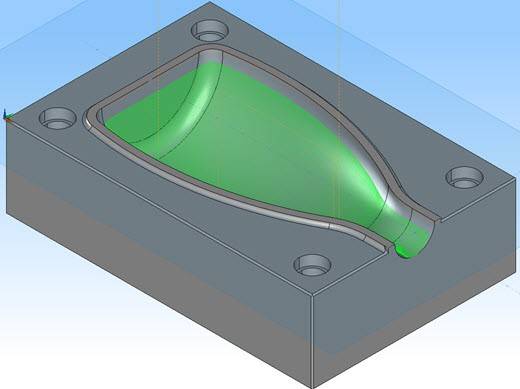

OneCNCXR6 has new finishing tool paths that are set to revolutionize the ability of finish machining 3D models with a unique method of automated 3D offset boundary tool paths. Singular or multiple surfaces of a model can be selected for area machining without the need to create boundaries. OneCNCXR6 automatically creates these 3 D offset boundaries so that the whole area right to the edge is machined. This now makes it possible to select surfaces and use a different sized tool to the next adjacent surface as an example. OneCNCXR6 also now provides a complete constant offset 3D boundary machining controlled by the part boundary or custom created boundaries.

OneCNCXR6 includes all of the conventional machining strategies of previous systems including planar, Z Level, pocket, constant offset, radial, spiral and pencil tool paths, all of these have been enhanced to take advantage of new tolerances optimization and advanced operating systems. OneCNCXR6 has taken these strategies further by refining tolerances and finishes that help to reduce machining time and increase tool and machine tool life.

OneCNCXR6 now contains ability to allow for expansion of functionality into may other areas of CAD and CAM during the life of the software. Our current users know OneCNC constantly adds new features and functionality on an ongoing basis during the life of the software.

OneCNC is now a leading CAM solution providing users with productivity, reliability and flexibility. Improving these attributes in any company helps increase profitability.

OneCNCXR6 new features list can be found here >>

OneCNC Benelux, Hurco GmbH and Hagro Precise BV invite you to attend a OneCNC Seminar.

OneCNC Benelux, Hurco GmbH and Hagro Precise BV invite you to attend OneCNC a seminar, where XR6 the new OneCNC release will be featured. This seminar will be explaining the benefits and use of the new HS strategy for milling and demonstrated on Hurco machines with tooling from Hagro Precision BV.

For pre-milling or rough machining, it is important to remove as much material as possible in the shortest possible time. This seminar will be demonstrating the high milling Material Removal Rate (MRR) using maximum machining efficiency with reduced machine time. The demonstration will show this high material removal rate can be obtained while maintaining part quality and longevity of the machine and extending the tool life of tools.

Additionally OneCNC Benelux will show in more detail the advantages of CAM programming, which will show the simplicity of using this advanced technology as well as reducing your programming time.

When?

July 3, 2014 from 12:30 to 17:00 hours.

Where is the seminar being held?

In Schaijk where Hagro Precision BV have a well-equipped demonstration room and facilities to demonstrate how using CAD-CAM and a CNC machining centre can improve your efficiency and profitability.

Click here to register for this event:

OneCNCXR6 Product ReleaseOneCNC Product Release Announcement

OneCNC is proud to announce OneCNCXR6 as a new version of the software is currently in BETA testing prior to release to new customers or existing users.

OneCNC plans to have a sneak preview of OneCNCXR6 available at the MACH2014 exhibition in Birmingham in April 7 – 11 2014.

OneCNCXR6 presently being BETA tested and due to be released shortly and is to be highlighted on stand 5764 in Hall 5 at the NEC in Birmingham, UK from 7-11 April 2014.

OneCNC’s Marketing Manager Jake Dewar says: There are many exclusive new features in OneCNCXR6 including 2D and 3D total collision checking for tooling and machined parts. This is totally integrated with the Tool Library, and the Holder Library. OneCNCXR6 continues the tradition of having a free maintenance plan for the life of the software ensuring that the software is kept up-to-date with free downloads and support from the update server. OneCNCXR6 is the most technologically advanced release developed in the 30 plus years history. OneCNC is supporting all users who have purchased New OneCNC systems since the 1st March 2014 an automatic free upgrade to the equivalent OneCNCXR6 version when released.

Amongst the new and enhanced functionality available in OneCNCXR6:

OneCNCXR6 utilizes the latest Windows 8 technologies including native 64-bit support for users of the 64-bit version of Windows resulting in superior performance, especially when working on large or complex designs. OneCNC understands that many users in manufacturing still use Windows XP and still supports these users with an automated installation of 32 Bit versions.

OneCNCXR6 is designed to take advantage of the latest multi-core systems. Multi-core depending on the operating system support can dramatically increase speeds generation of some complex tool paths and is beneficial not only when generating multiple operations or performing simulation tasks, but also when generating a single tool paths.

All of this happens from an automated installation that checks the operating system being used and installs the most advanced version to suit the Windows version of the user’s PC.

OneCNCXR6 HS Pocketing has been greatly enhanced and now has automated ability for handling pockets where some boundaries are partially open and partially closed.

OneCNCXR6 Feature recognition drilling has been enhanced to automatically handle multiple depths of drilling with the same tool while still maintaining cycle utilization ability.

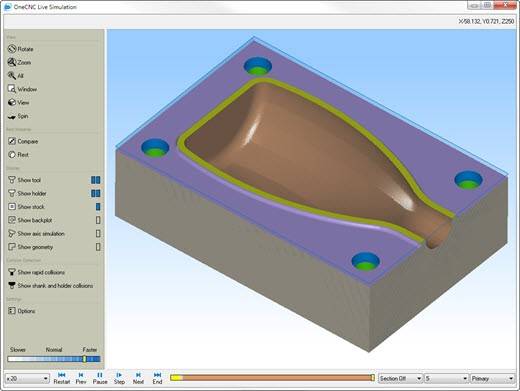

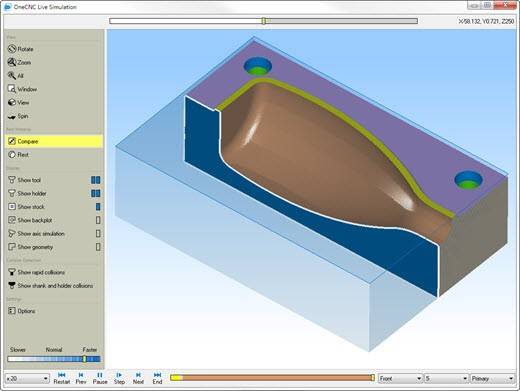

OneCNCXR6 Simulation has been re-designed and now includes a rich-array of features for checking the machining operation before sending the program to the machine tool. These features include Collision Checking of the tool flank cutting length, the tool length, and holder interference dimensions.

CNCXR6 Simulation has a Dynamic Instant Compare feature to analyse and compare the model of the part being machined to the original model.

OneCNCXR6 is designed to generate the smoothest tool paths possible from the model resulting in reduced machining time, improved surface quality, less tool wear and extended machine tool life. OneCNC features innovative tool path strategies, like HS Milling, that typically reduces roughing time by a factor of 70% or more compared to conventional roughing, and increases tool life by as much as 50% depending on material hardness.

OneCNCXR6 has new Finishing Tool Paths that are set to revolutionize the ability of finish machining 3D models with a unique method of automated 3D offset boundary tool paths. Singular or multiple surfaces of a model can be selected for constant offset machining without the need to create boundaries. OneCNCXR6 automatically creates these 3 D offset boundaries so that the whole area right to the edge is machined. This now makes it possible to select surfaces and use a different sized tool to the next adjacent surface as an example. OneCNCXR6 also now provides a complete constant offset 3D boundary machining controlled by the part boundary of custom created boundaries.

OneCNCXR6 includes all of the conventional machining strategies including planar, Z Level, pocket, constant offset, radial, spiral and pencil familiar all of these have been enhanced to take advantage of new tolerances optimization and advanced operating systems. OneCNCXR6 has taken these strategies further by refining tolerances and finishes that help to reduce machining time and increase tool and machine tool life.

OneCNCXR6 now contains ability to expand the functionality included into may other areas of CAD and CAM during the life of the software as our current users know OneCNC constantly adds new features and functionality on an ongoing basis.

OneCNC is now a leading CAM solution providing users with productivity, reliability and flexibility. Improving these attributes in any company helps increase profitability.

OneCNC has offices in the UK, Italy, France, Japan, USA Florida, and USA California, Germany, Benelux, Turkey, Denmark, Australia, Poland, Mexico, India, Korea, South Africa, Sweden, Ireland and Indonesia and through this network is currently supplying product to more than 40 countries.

Further announcements will be made when OneCNC is closer to being released

OneCNC Australia