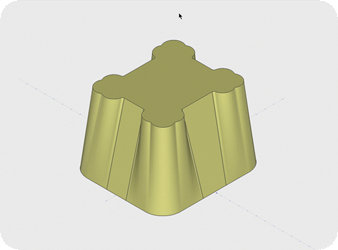

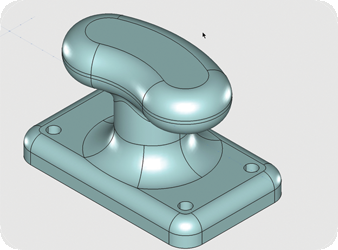

CAD/CAM (computer-aided design and computer-aided manufacturing) refers to computer software that is used to both design and manufacture products.

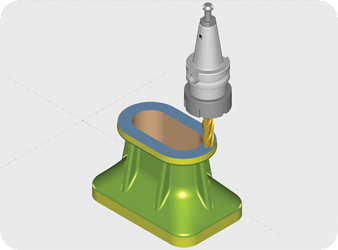

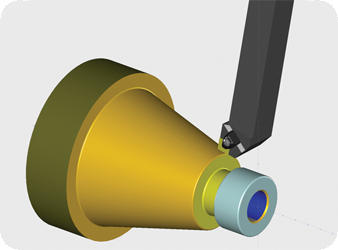

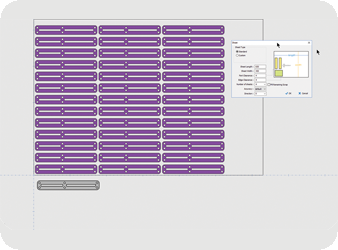

CAD is the use of computer technology for design and design documentation. CAD/CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software to generate tool paths that drive the machines that turn the designs into physical parts. CAD/CAM software is most often used for machining of prototypes and finished production parts.